The Silbitz biomass power plant in Thuringia, Germany, produces electricity (5.6 MW) and district heat (3 MW) from waste wood. In order to keep its production competitive, a high degree of availability at the plant is required. This was not satisfactory in Silbitz. The reason was the furnace: Heavy slagging on the walls resulted in short boiler operation periods and frequent downtimes. Since 2011, four shock pulse generators have been cleaning the plant during ongoing operation. This has enabled the amount of slagging to be minimized and boiler operation periods to be lengthened in the long term.

Andree Michaelis, operations manager at the biomass power plant in Silbitz, comes straight to the point. “Since we started cleaning the furnace and radiation pass as well as the convection passes regularly with four Shock Pulse Generators, we’ve kept the boiler efficiency at a constantly high level throughout the entire boiler operation period.”

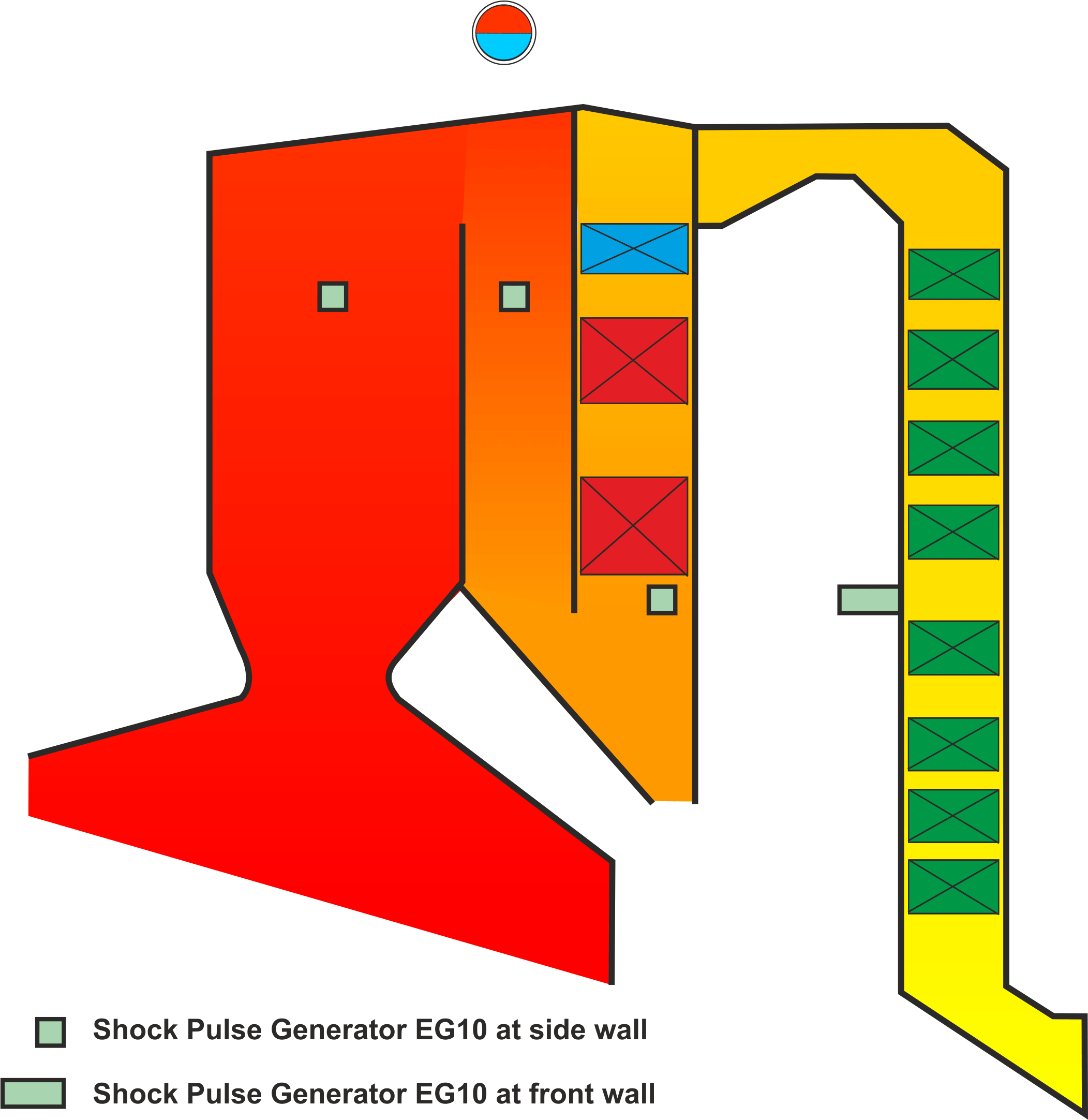

The biomass power plant went into operation in 2003. The vertical boiler consists of a furnace, a radiation pass, a convection pass and an economizer pass (see Figure 1). The engineering company Standardkessel Baumgarte did not envisage installing a cleaning system in the furnace and radiation pass for the removal of deposits during operation. From the start, the superheater and economizer passes had been equipped with steam sootblowers (rotary and retractable sootblowers by Rosink).

Boiler fouling caused frequent downtimes

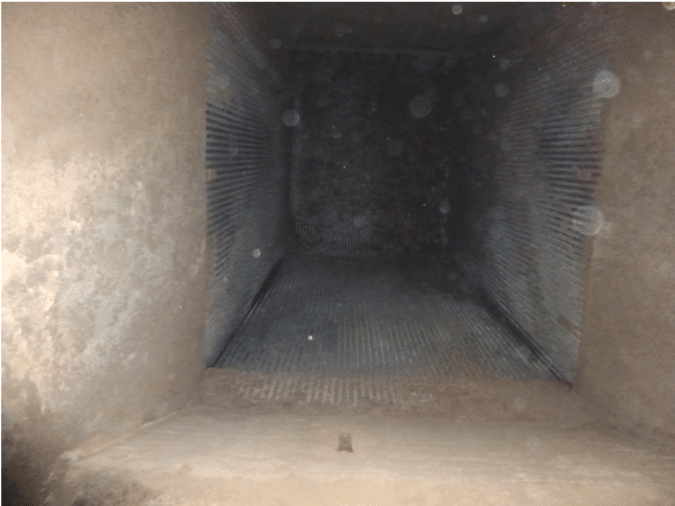

However, after just a short period of operation, the boiler showed signs of heavy fouling. In the furnace, slagging and fouling often reached such a high level (see Figure 2) that the sheer weight caused it to fall off from the side walls, dropping down and blocking the ash discharge, or damaging the grate. As a result, the boiler had to be shut down for cleaning and repair respectively.

“The frequent downtimes massively reduced our boiler operating times. This was an untenable situation and we had to come up with some solutions,” states Mr. Michaelis. The plant operator found the answer at Explosion Power. Since October 2011 four Shock Pulse Generators EG10 have been up and running at the plant.

Shock pulse interval of 24 hours instead of eight sootblowers

The Shock Pulse Generators (SPGs) cater for the improved cleaning at the entire boiler. The first SPG prevents slagging and fouling in the furnace (see Figure 2), with the second tasked with cleaning the radiation pass. The third supplements the sootblowers in the convection pass to clean superheater 1 better and to reduce the operation of the soot blowers, and the fourth makes the sootblowers in the economizer pass redundant.

By using SPGs in the furnace and radiation pass, the flue gas temperature can be kept at a constantly low level at the convection pass inlet. This reduces the level of corrosion in the superheater bundles and improves the cleanability of the bundles.

In the convection pass, only the sootblower between the two superheaters and the one between the superheater and the evaporator are still in use. Thanks to the lower inlet temperatures the deposits left on the superheaters are less sticky. The tubes can be cleaned more easily and the sootblowers have to be used less frequently. During the first six weeks following a boiler overhaul, the sootblowers in the convection pass do not have to be used at all.

The plant could fully retire the eight sootblowers in the economizer as a single Shock Pulse Generator with a shock pulse interval of 24 hours does the job of all the sootblowers now.

In October 2017, a fifth SPG was also installed in the third pass, between superheater 1 and superheater 2, to further optimize the cleaning of superheater 2.

Marked increase in availability …

As the boiler is now automatically cleaned by the Shock Pulse Generators system, availability has considerably increased, with downtimes reduced to a minimum. Mr. Michaelis says, “Between cleaning intervals, the plant now always runs in the nominal load range. We’ve also been able to reduce the flue gas temperature at the furnace ceiling to a maximum of 850°C.”

… and other considerable benefits

The shock pulse generators also lengthen the service life of the boiler and simplify its maintenance. Mr. Michaelis explains further. “Unlike the sootblowers, the shock pulse generators don’t cause any abrasion on the pipe surfaces. This means that we could remove the protective shells on the economizer tubes.”

As the sootblowers are used much less often, this has an effect on the overall energy balance of the biomass power plant. Thus, electricity production has risen by 2%. In addition, less demineralized water has to be prepared. “As our sootblowers are being used much less frequently, we’ve been able to halve our water consumption,” smiles Mr. Michaelis.

Simple maintenance – by the customer on site

The biomass power plant in Silbitz has had its own service technicians trained in the maintenance of the Shock Pulse Generators. This means that they are able to carry out servicing of the SPGs themselves. This is due after 3,000 shock pulses or every twelve months. Spare and wear parts are bought directly from Explosion Power GmbH.

Biomass power plant in Silbitz

- Boiler output: max. 27 MWth

- Fuel input: approx. 55,000 t/a (waste wood A1–A4)

- Gross electrical output: 5.6 MW

- Annual net electricity output: 39,660 MWh/a

The power plant was built by Standardkessel Baumgarte and has been operated by PNE Biomasse GmbH since 2003. Four EG10 shock pulse generators have been in operation here since 2011, with a further SPG added in 2017.