Copper Smelter

Bulgaria

Overview

Boiler Data

- Boiler Design: Horizontal (twin type design)

- Steam Flow: 65 t/h @ 48 bar saturated steam

- Dimensions: 12 m H x 6 m W x 45 m total length

- Fuel / Boiler Type: Waste heat boiler installed after flash copper smelter furnace

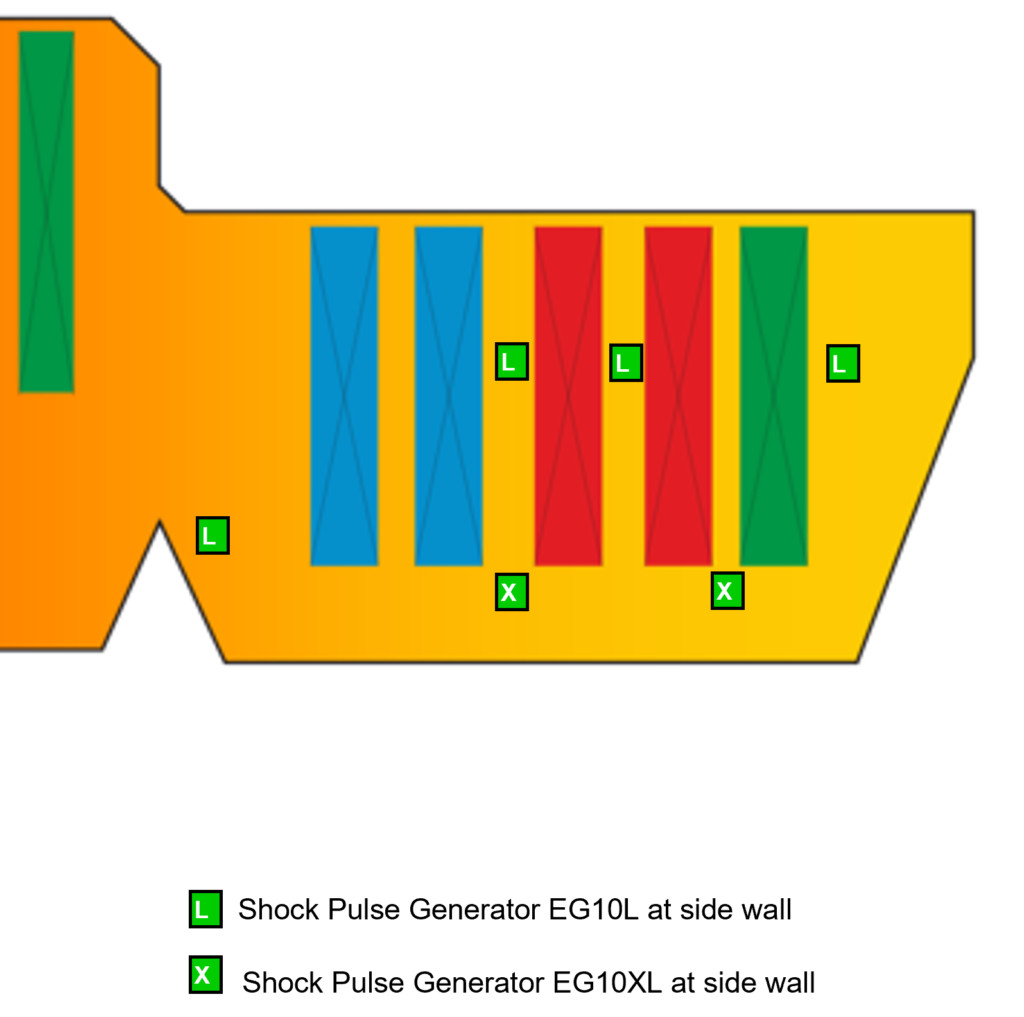

- SPG in Operation since: 4 EG10L from 2016, additionally 2 EG10XL from January 2022. All in the convective section

- Shock Pulse Interval: Approx. 1 SP/h, adapted by operator;

- SPGs are combined with existing mechanical rapping system

Significant Improvements of the Cleaning Process

Cleaning effect very good, gas exit temperature reduced from 450°C by 20K after the 2016-installation

- Throughput production increased by over 20% even since the installation in 2016

- Equalizing of the gas exit temperature since 2022

- Operator is very satisfied with the SPGs

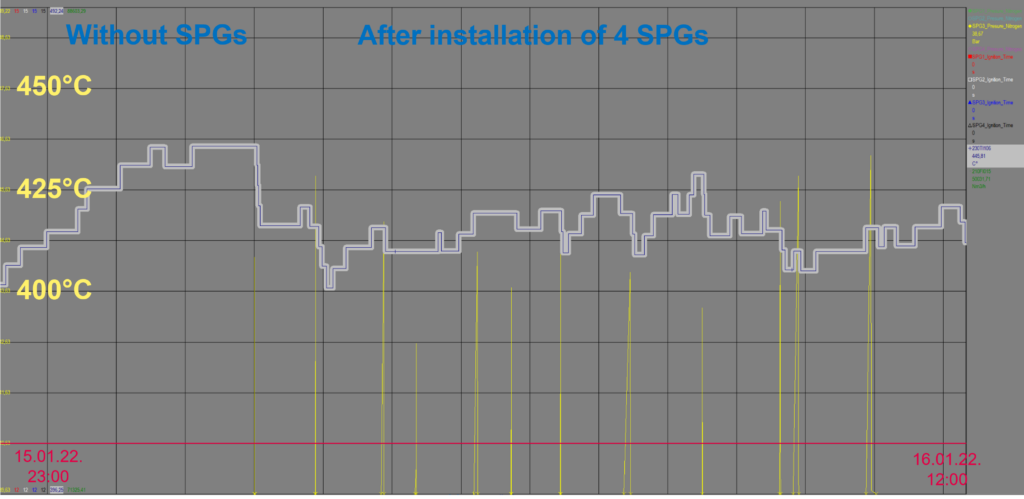

Reduction of average flue gas temperature by 20 K by EG10L

The four Shock Pulse Generators EG10L achieve an average flue gas temperature reduction of 20K, since their commissioning in 2016.

The chart shows the result before the installation of the additional 2 EG10XL in January 2022.

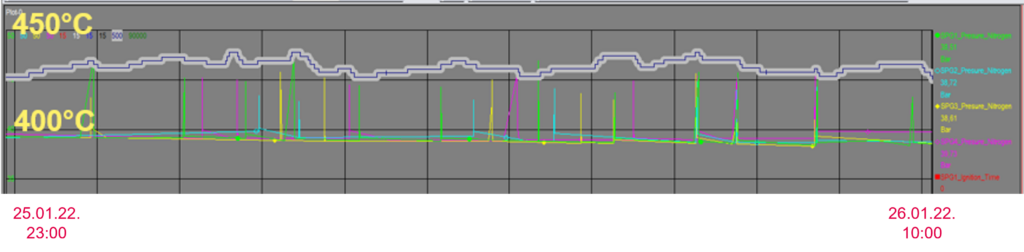

Flue gas temperature further reduced by two additional EG10XL

The two additional Shock Pulse Generators EG10XL achieve a further reduction of average flue gas temperature, since their commissioning in January 2022. And the temperature fluctuations are reduced.

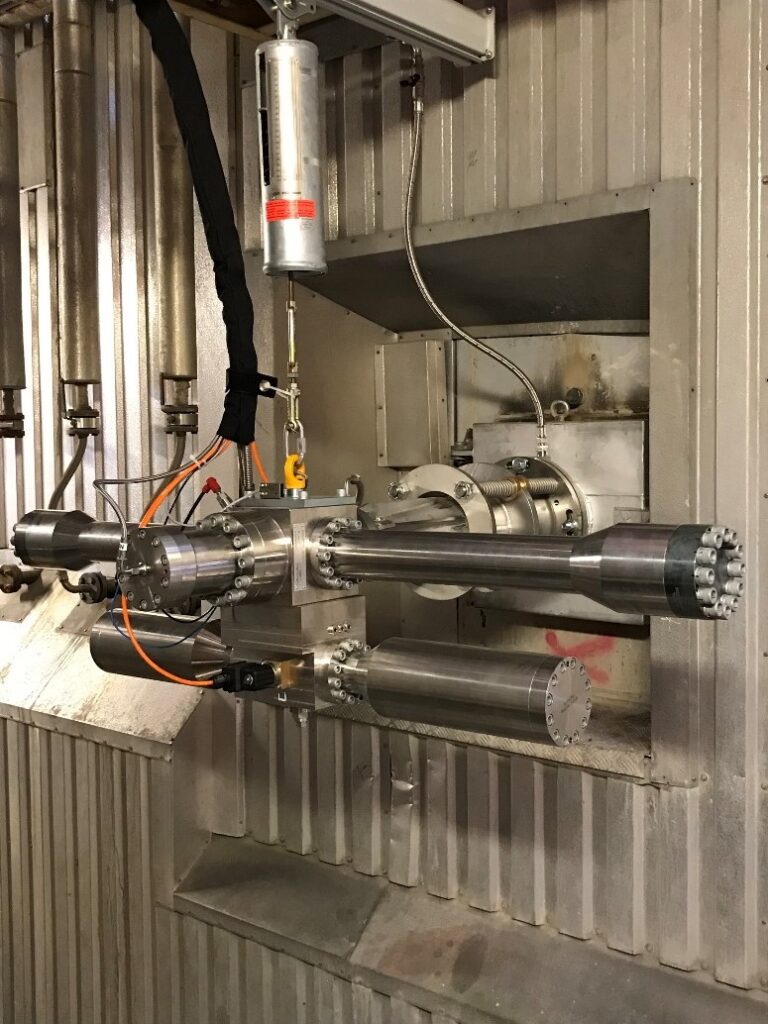

Small space requirement is advantageous, for retrofit and new build projects

as an example

Illustration of the EG10L and EG10XL types installed in the plant, which slightly differ only in the dimensions of the combustion cylinder.