Explosion Power GmbH installed 4 TwinL SPGs into a Supercritical Pulverized Coal Boiler 660 MWel capacity which operate successfully in support of boiler cleaning and keeping the required flue gas outlet temperature within design specifications (inlet to SCR catalyst elements). For the next phase the Thai power producer intents to install additional 4 TwinL SPGs for saving feed water and steam and for cycle optimization.

GHECO-One Co., Ltd. is a joint venture between a leading private producer of electricity and industrial land / utilities companies operating in Thailand,

The joint venture was formed in 2007 with the objective to produce and supply electricity to Electricity Generating Authority of Thailand (EGAT) under the Independent Power Producers (IPP) program. GHECO-One plant is operated in line with international standards, using subbituminous coal by in the state-of-the-art environmentally friendly technology including NOx-, dust emission and SO2 reduction systems. The construction started in 2009 after receiving Environmental Health Impact Assessment (EHIA) approval by the Office of Natural Resources and Environmental Policy and Planning (ONEP). Commissioning started in 2010, commercial operation by 3rd quarter 2012.

The Objective

The Supercritical Pulverized Coal fired Boiler of 660 MWel. capacity produces 2’079 t/h steam of 243 bar and 568°C incinerating sub-bituminous coal. To protect the SCR catalyst elements, it is necessary to maintain the boiler flue gas exhaust temperature below 400°C, whereas the temperature tend to increase within 7 days after a manual cleaning from 380°C up to 410°C. This is due to ash accumulation on the Primary Re-Heater and Economizer. The boiler is equipped with a total of 92 soot blowers, whereas 24 long retractable soot blowers are located in the furnace and 24 of similar type are installed in the back-pass. Pending on coal qualities slagging and fouling indexes the soot blowers may operate 24 hours a day 7 days a week.

The Solution

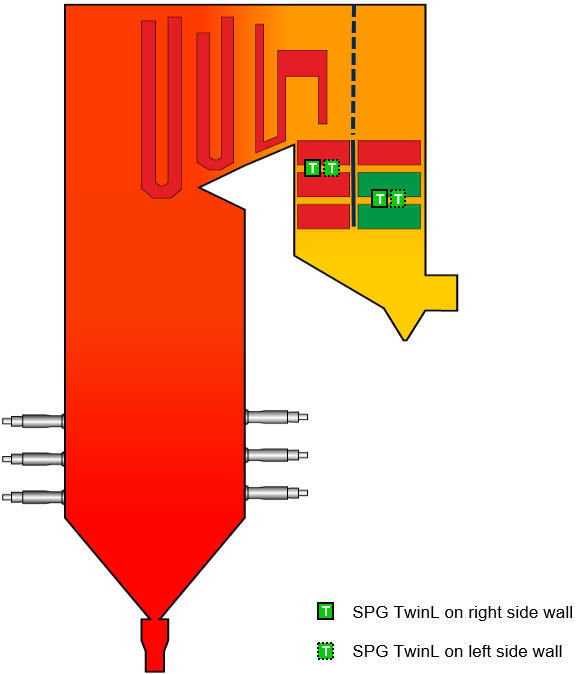

Explosion Power GmbH has been awarded to mitigate the unfavorable conditions upstream of SCR in a 24m wide back-pass chamber. Gheco-One then installed 4 Shock Pulse Generators TwinL – as two per side – to assist the soot blowing system keeping the economizer clean in order to pick up exhaust heat improving/stabilizing boiler efficiency but most important – protecting the sensitive SCR element from excessive heat/accelerated decay. The back-pass mainly accumulates small ash particles that are sufficiently removed by the 4 TwinL’s. The system was installed and commissioned by Explosion Power with excellent support of our local distributor and competent supporting partner Vannetto Pte. Ltd. in April 2018. Vannetto also carries out all service and maintenance works for the installed TwinL.

Fig. 2: Schematic boiler picture by Explosion Power GmbHBefore the operation of the 4 Shock Pulse Generators TwinL the back pass had to be cleaned additional to the soot blowers by one shift of manual cleaning once a month.

The shock pulse intervals are set to 60 minutes, which has proven to be the most suitable pulse frequency.

Some of the original soot blowers are still operated with an unchanged operating cycle sequence. During the actual phase – called phase 1 – the operator may change the shock pulse interval according to the boilers requirements depending whether they operate full load or not. These decisions are taken by the Shift Leader on duty at that time. Since then, the outlet temperatures upstream of SCR are kept constantly at 380°C.

Usually the signal for activation the shock pulse is released via the distributed control system. However, the DCS operators did not allow any interaction with their system while the boiler was operational. Therefore, an alternative solution had to be found which was connecting the hardwired signal through the soot blower’s connection. In the final state all the activation signals will be connected to the central DCS. Training to all operations shifts were given to ensure all personnel can safely operate the system.

The Next Phase

To continue mitigation slagging, clinker and to improve fouling solutions, phase 2 of the project will include additional Shock Pulse Generators in the back-pass to further assist the soot blowing systems.

As soon as 4 additional TwinL SPGs will be installed, the goal will be to stop 16 up to 24 long retractable soot blowers. The target is to save feed water / steam and reduce the number of the originally installed soot blowers by application of the Shock Pulse Generators having even an improved cleaning efficiency compared to the soot bowers. At least 2 long retractable soot blowers will be kept in operation per SPG. The whole boiler cleaning system will be activated from the central DCS.