In the fall of 2020, Explosion Power GmbH launched the Shock Pulse Generator SPGr series. With this innovative further development of the existing technology for automated industrial boiler cleaning, Explosion Power GmbH was able to introduce a product series that enables even higher cleaning performance with reduced maintenance and space requirements. These product advantages already led to a considerable number of orders in 2021 and to a lot of positive feedback from customers after commissioning of the new SPGr.

Development and introduction of the SPGr series

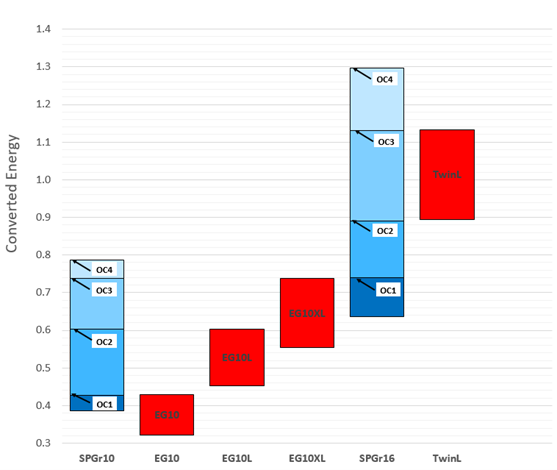

There were already over 650 SPG units of the EG10 and TwinL product series successfully in operation when Explosion Power started developing a new series in 2017. All the knowledge from over 7 years of operating experience of the existing EG10 and TwinL series was considered. Based on theoretical modeling, prototype testing in the company’s own endurance test facility and passing a deployment in a boiler of the WtE-plant Zurich, the final concept of the SPGr was determined. Explosion Power’s continuous efforts to achieve a high degree of standardization have made it possible to cover the entire power range from EG10 to beyond TwinL with only two product types of the new SPGr series (see Fig. 1). As with its predecessors, the SPGr series is a high-quality product that enables customers to operate their boilers at optimum performance and thus maximize their benefits.

Major differences between the SPGr series and the EG10 series are the use of air instead of oxygen as the oxidizing medium and the stoichiometric ratio of combustion. The resulting combustion conditions allow a massive extension of the maintenance interval to 7,000 Shock Pulses.

Air is supplied by an air compressor unit which is optimally matched for operation with the SPGr. Additionally, the SPGr series require less space in comparison to the other products.

Rapid market launch and stable operation

Since the market launch of the SPGr series in the fall of 2020, more than 50 SPGr have been sold worldwide. 25 of them have already been put into operation. By the end of November 2021, these SPGr have impressively demonstrated stable operation during more than 120,000 Shock Pulses and contributed significantly to optimized cleaning of the boilers concerned.

Additionally, more than 200,000 Shock Pulses have been carried out in Explosion Power’s permanent test facility by prototypes, pilot series units and three series units.

Significant improvements in boiler operation led to rapid, positive customer feedback

Numerous new customers as well as existing customers are already applying the SPGr series. Significant improvements in boiler operation have been demonstrated within relatively short periods of time after commissioning of the respective SPGs, resulting in positive customer feedback. Several customers have agreed to a regular detailed analysis of the boiler operating data to be able to optimally choose the operating settings of the SPGr.

The waste incineration plant Renergia Perlen is an important example. In 2020, the waste incineration capacity was increased to 120% of the design value. This results in significantly higher flue gas and fly ash volumes. The three EG10Ls installed in the three vertical radiation passes since the initial start-up in 2015 continue to ensure a constant low flue gas inlet temperature into the horizontal pass by means of an increased number of Shock Pulses. On the other hand, fouling in the horizontal pass had increased considerably. Since August 2021, therefore, three SPGr10s per boiler have been operated in the horizontal pass. Together with the original pneumatic rapping devices, the superheater bundles can thus be kept for a long term in a sufficiently clean condition. A boiler travel time of 18 months is to be achieved.

Future prospects

Since 2009 totally more than 800 SPGs were installed worldwide. With the SPGr series, Explosion Power is ideally positioned to solve demanding boiler cleaning requirements, also for large boiler capacities. Significant growth is expected in existing and new markets also in year 2022. The production facility in Niederlenz, Switzerland has got a capacity of over 200 SPGs per year.