Biomass Boiler

Germany

Overview

- 28 t/h steam capacity, 46 bar, 425°C

- 4 pass vertical boiler

- Boiler width: 3.9m; 3rd pass: W3.9xL2.2m

- Bundle height: 0.7 / 1.9 / 1.9 / 1 m

- 4 x EG10, since 10/2011 (1st pass; 2nd pass;

- 3rd pass: below SH1; 4th pass: middle of pass)

- Very positive cleaning effect in 1st pass: large build up at the walls can be completely avoided. Before, such build ups made it necessary to stop the plant, when they fell down onto the grate.

- Because of better cleaning of 1st and 2nd pass, the flue gas temperature at inlet to 3rd pass is constantly lower.

- Due to the lower flue gas temperature, the cleaning of the third pass with 1 EG10 and 3 sootblowers is more efficient. Therefore additional manual explosive cleaning is not necessary any more.

- 1 EG10 can keep the Economizer clean, sometimes with additional sootblowing.

- The sootblower operation in 3rd and 4th pass was strongly reduced.

- Plant supplier: Standardkessel

- Plant operator: PNE Wind

Before installation of Shock Pulse Generator:

Year 2010, after 10 weeks of boiler operation

Large slagging / deposits are visible at the membrane walls and at the refractory.

Several times, large size slag lunks were falling down after some time due to heavy weight and blocked the deslagger or damaged the stoker

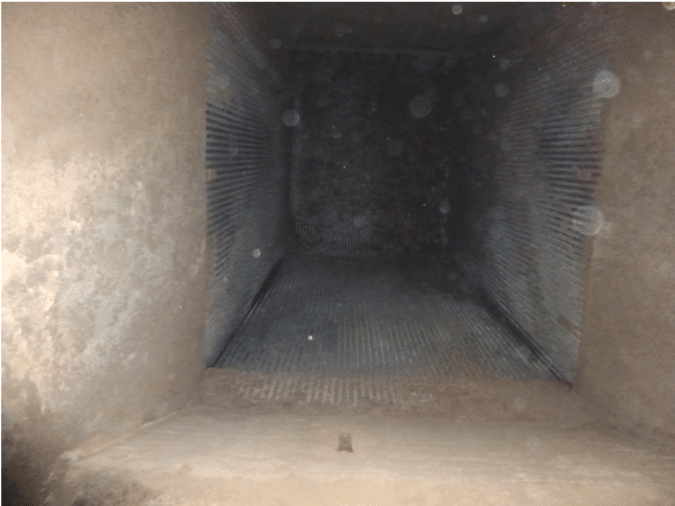

After installation of the Shock Pulse Generator: Year 2015, after 12 weeks of operation

Slag and deposits are cleaned off from membrane wall and from refractory by the Shock Pulses of the SPG.

There were no further blockages of the deslagger, nor damages to the stoker.