Biomass Boiler (Ref. 1)

Spain

Overview

Boiler Data

- Boiler Design: vertical with two-drums-vertical evaporator and vertical economizer

- Steam Flow: 105 t/h @ 68 bar/ 485°C

- Dimensions: 18.9 m H x 4.5 m W x 10.7m L (excl. economizer in a separate section)

- Fuel / Boiler Type: Biomass/Fluidized bed

- SPG in Operation since: 1 EG10XL from November 2019, upstream of evaporator

- Shock Pulse Interval: 45 minutes SP by DCS activation

- SPG is supporting the original soot blowers

Significant improvement of the Cleaning Process

- Operator is very satisfied with the SPG

- Cleaning effect sufficient the keep the steady flue gas temperature of approx. 440°C downstream of the evaporator

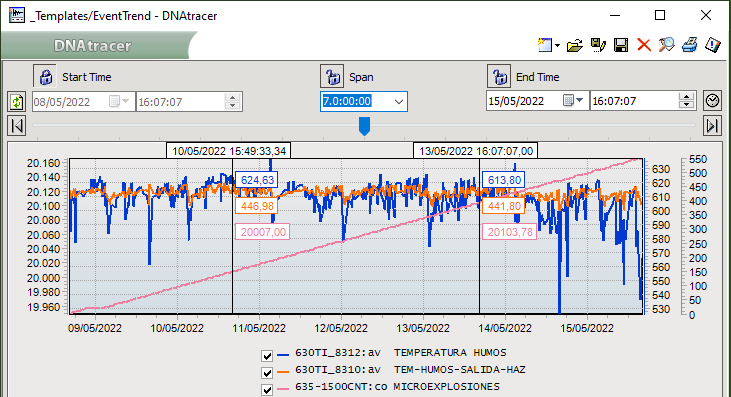

Equalizing of average flue gas temperature downstream of the evaporator (7-days trend)

The Shock Pulse Generator EG10XL is activated by the DCS in a frequency of 45 minutes. The cumulation trend shows approx. 20.000 SP since the commissioning in 2019.

The temperature upstream of the evaporator is highly fluctuating around 600°C (blue curve), whereas the downstream temperature is equalized by 440°C due to the SPG (orange curve).

Day-report of the average flue gas temperature downstream of the evaporator

The temperature upstream of the evaporator is highly fluctuating around 600°C (blue curve), whereas the downstream temperature is equalized by 440°C due to the SPG (orange curve).

The shock-pulse counter shows approx. 20.000 SP since November 2019 (red stepped trend).

Location of the SPG and a view on the disassembled unit during the main maintenance after 3 years operation

Maintenance of the SPGs can be easily carried out while the boiler is in operation. The SPG will be disconnected from the boiler and the opening at the discharge nozzle is sealed against the negative pressure of the boiler. The main works at the SPG are exchange of wear parts like gaskets, which are exposed to short time high temperature during the Shock Pulse and checking of spare parts. Wear parts are exchanged, and spare parts are checked. The work can be done within one day.