Biomass Boiler

France

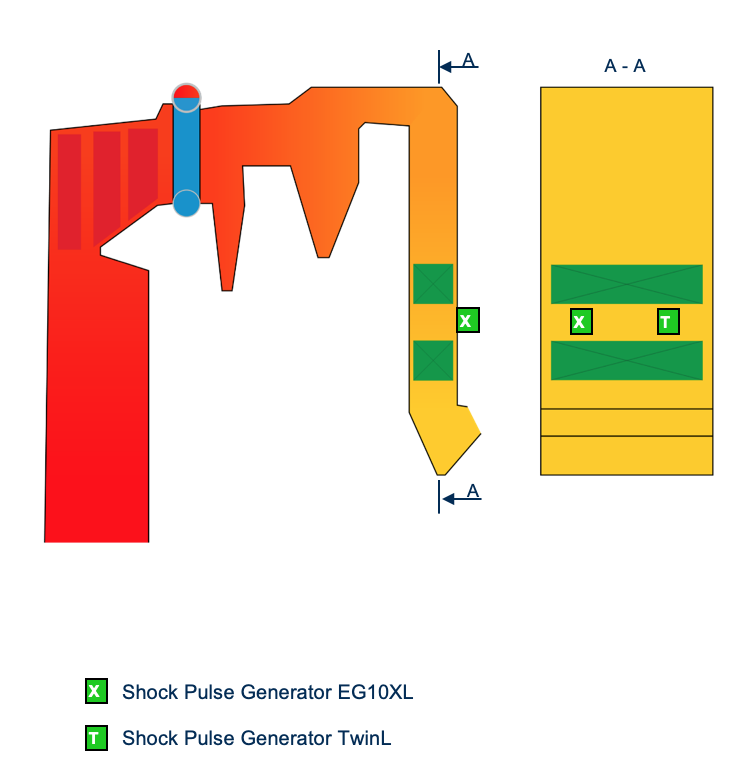

Overview

- 110 t/h steam capacity (83 MW), 16MWel, process heat and cooling water for adjacent industry

- Fuel: natural wood

- Dimensions ECO bundles:

- W 6.5m x L 2.5m x H 1.5m -PT 76mm, PL 73mm, tube diameter 31.8mm

- Finn geometry: 120mm x 70mm rectangular fin plates connecting two tubes

- Distance between fins: 19mm

- Manufacturer: Favier-Setrem

- Initial cleaning equipment: rake soot blower above each ECO bundle (10t/h steam consumption soot blowing 3x/day); 2 Nirafon sonic horns between bundles; manual online boiler cleaning every 14 days

- Since 07/2016: Shock Pulse Generators, 1x EG10XL, 1x TwinL; Shock Pulse Interval 1h

- Since installation of SPGs, the flue gas temperature difference over the ECO can be kept constant; without sonic horn, without repeated manual online boiler cleaning; mostly without use of sootblowers.

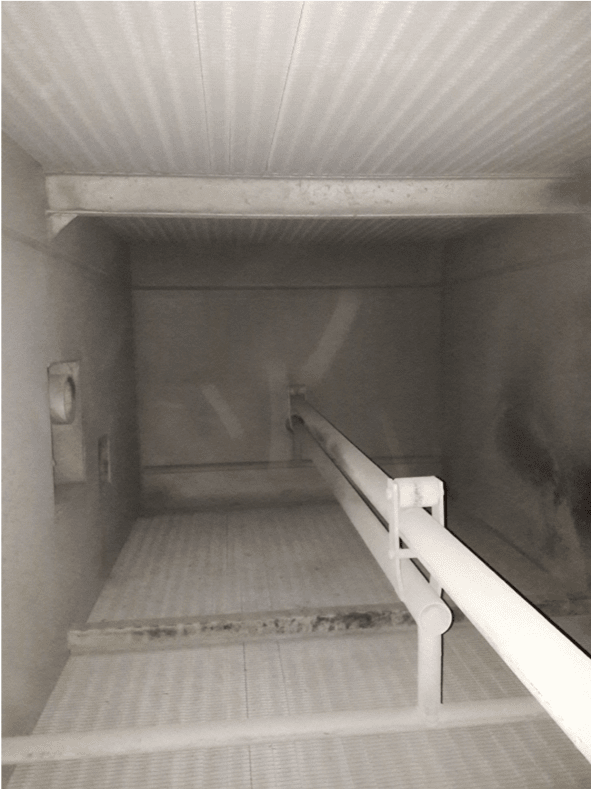

EG10XL discharge nozzle cleaning right side of finned tube ECO bundles. Rake soot blower stays installed.

TwinL 90° rotated cleaning left side of finned tube ECO bundles. Met tight installation restrictions outside of boiler.